Back to articles

How Flexible Busbar Solves Current Imbalance in Multi-Parallel Cables—Unlock Safer, Efficient Power Distribution

David Doe

10/30/2025

Why do multiple parallel cables always have one heating up first?

In the actual operation of electrical systems, have you encountered situations where multiple parallel cables have current deviation or shunting?

During parallel installation of cables, the actual current capacity is not a simple '1+1=2' relationship. Very likely '1+1=1.5' or even '1+1=1' phenomena may occur!

What exactly is cable current deviation?

In scenarios where multiple cables are used in parallel, ideally, the current in each conductor should be evenly distributed.

However, reality is often not the case. If current distribution among conductors becomes uneven, cable current deviation occurs.

What causes multiple parallel cable current deviation or shunting?

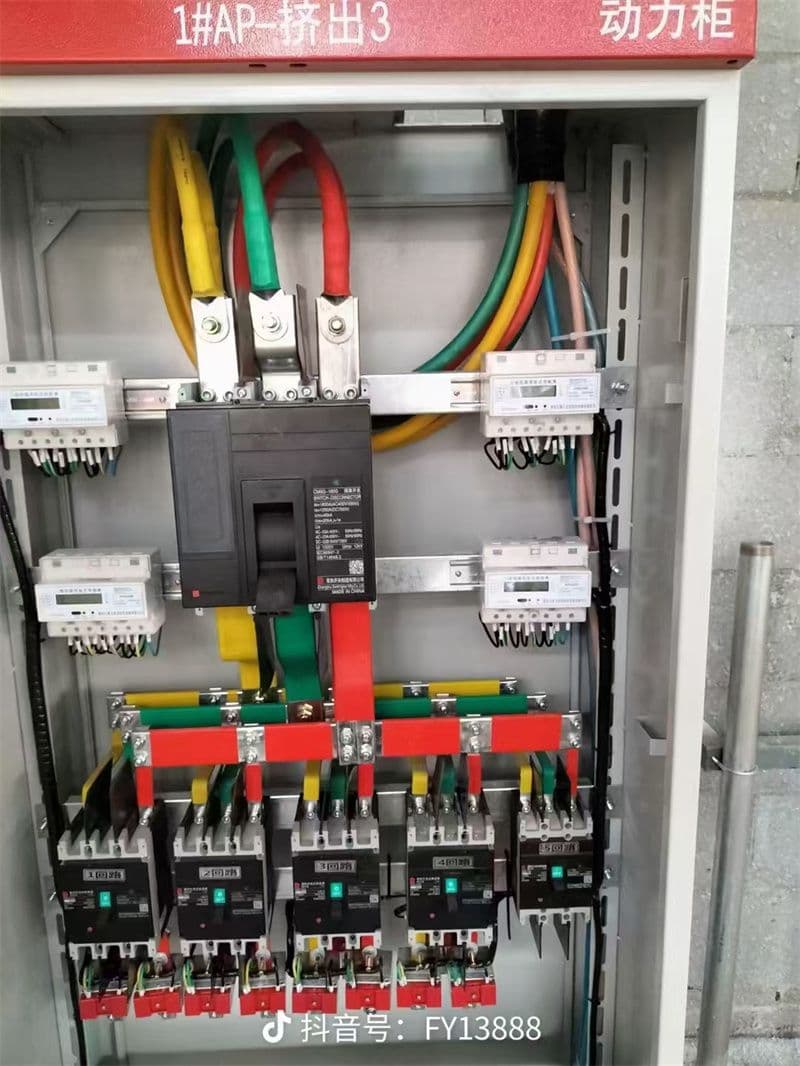

Cable current deviation is usually caused by multiple factors: ① Three-phase load imbalance is an important reason. ② Harmonic interference cannot be ignored. ③ Line faults are also factors leading to cable current deviation.

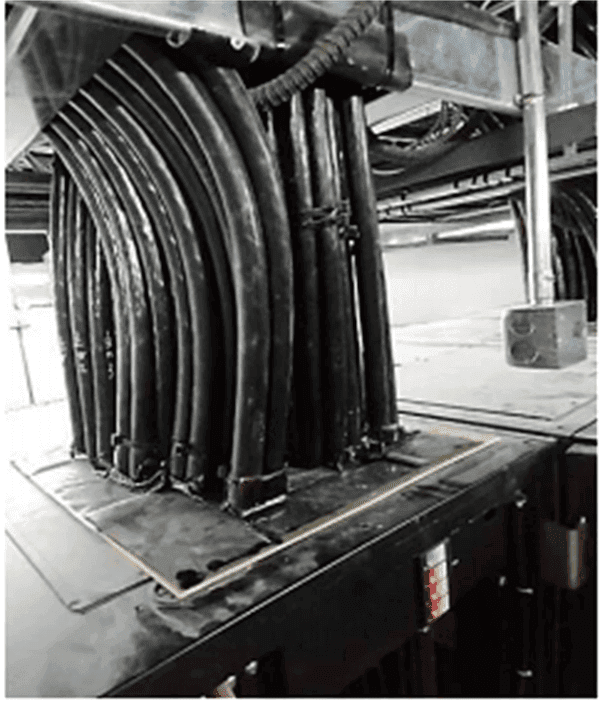

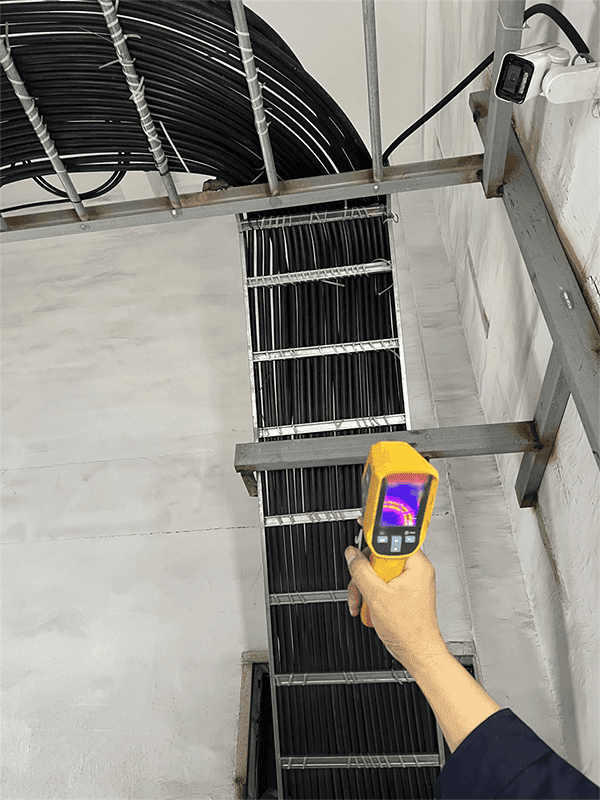

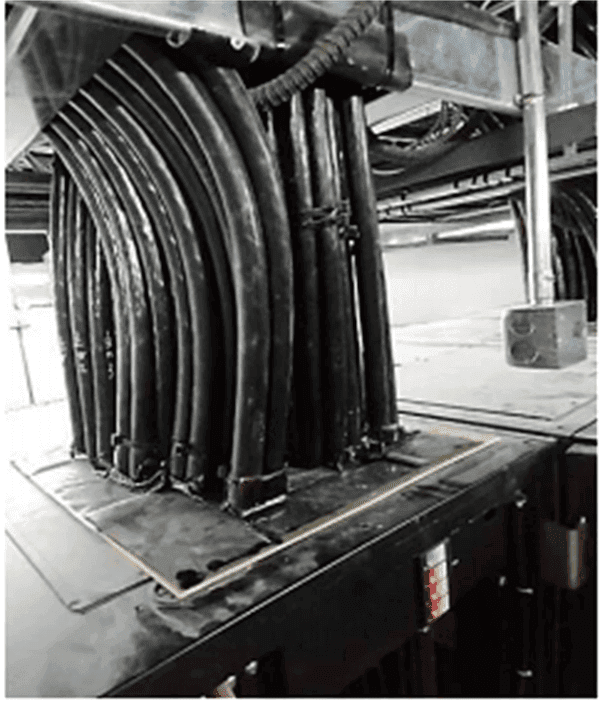

Especially noteworthy is that multiple parallel cables present numerous troubles during installation.

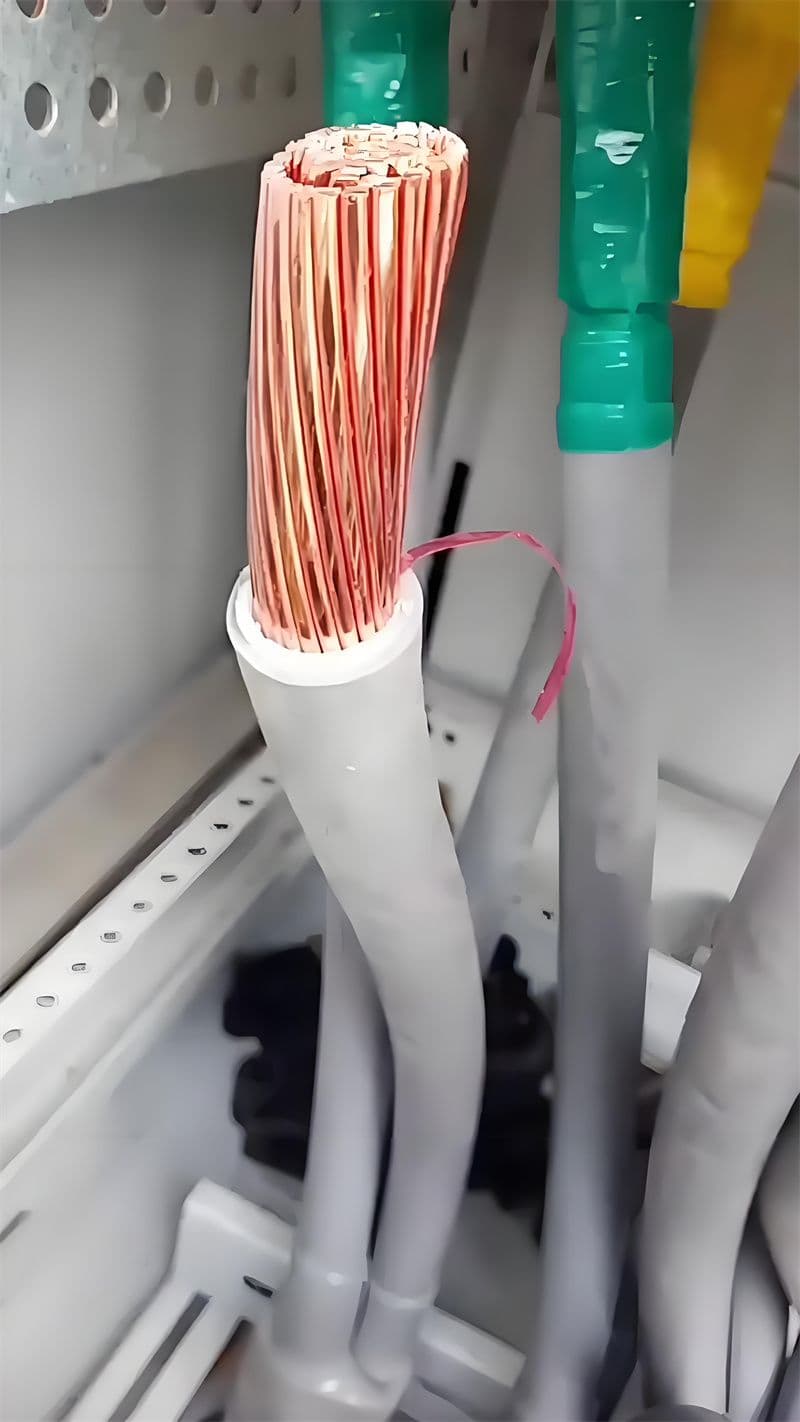

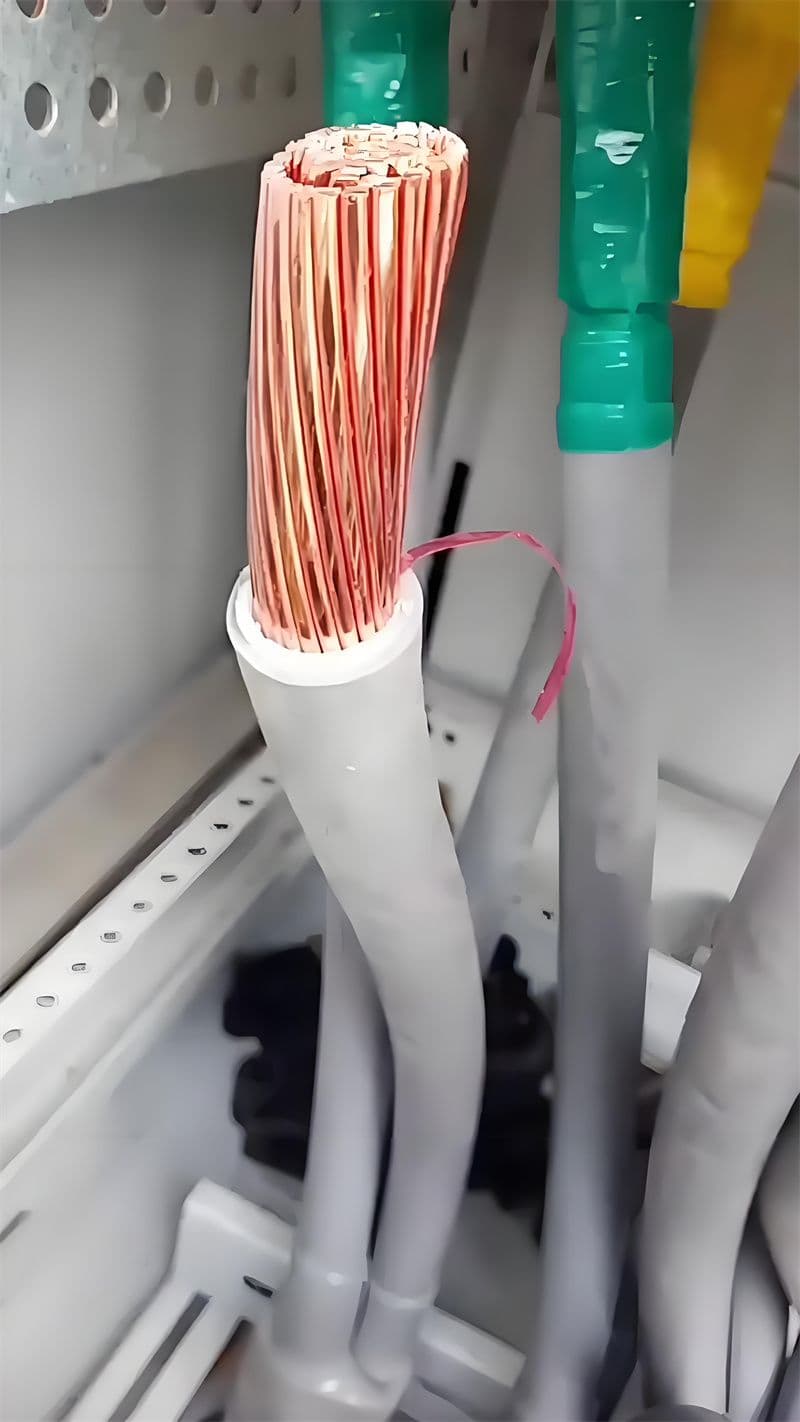

- If copper lugs are not properly made, such as loose compression of copper lugs, this will not only affect normal cable operation but may also further exacerbate current deviation.

- Or if contact surfaces are not properly connected, with oxidation, dirt, and other conditions, contact resistance will change, causing uneven current distribution.

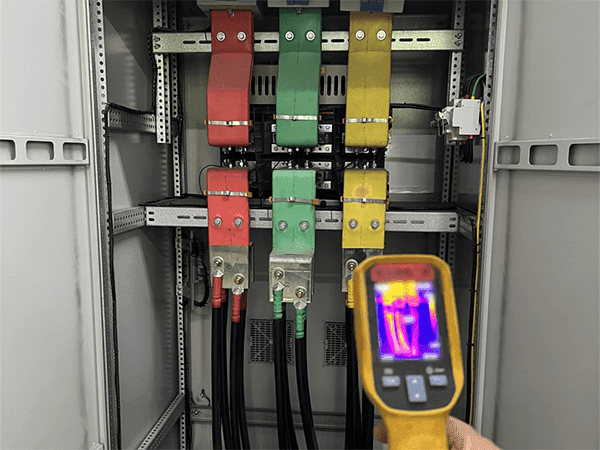

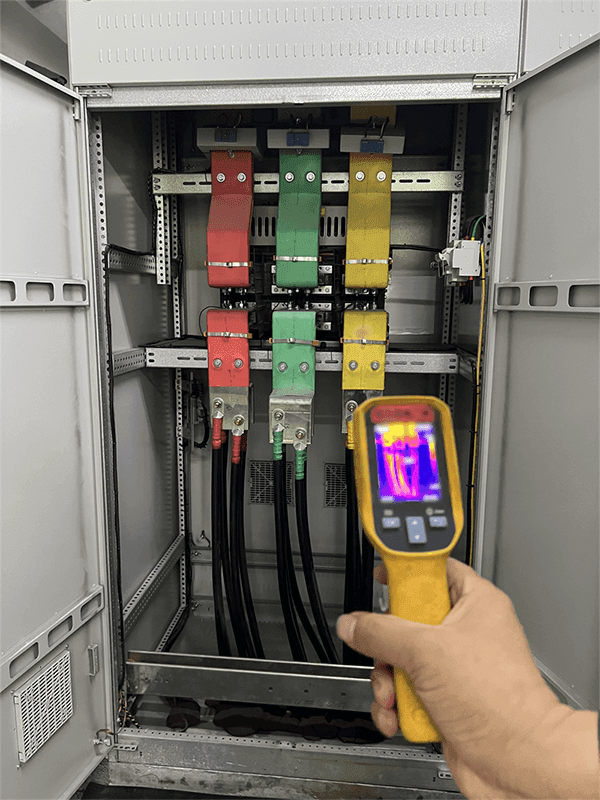

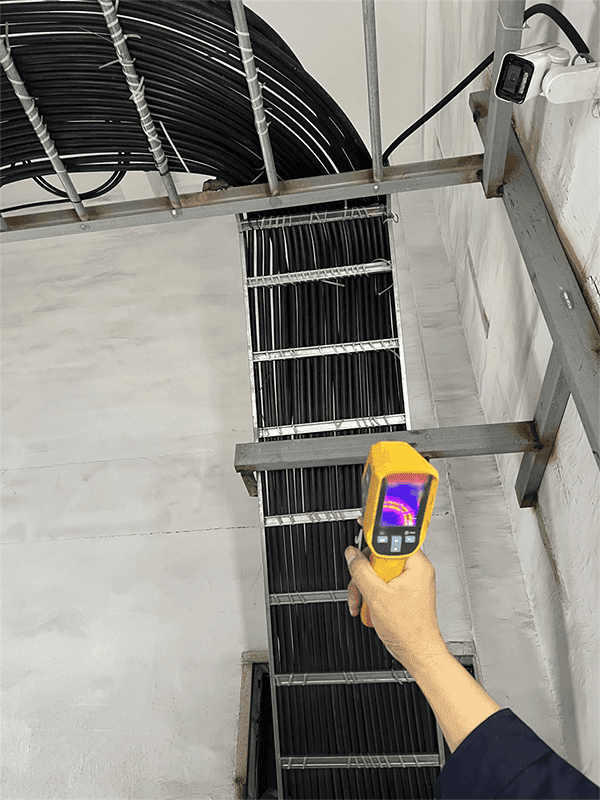

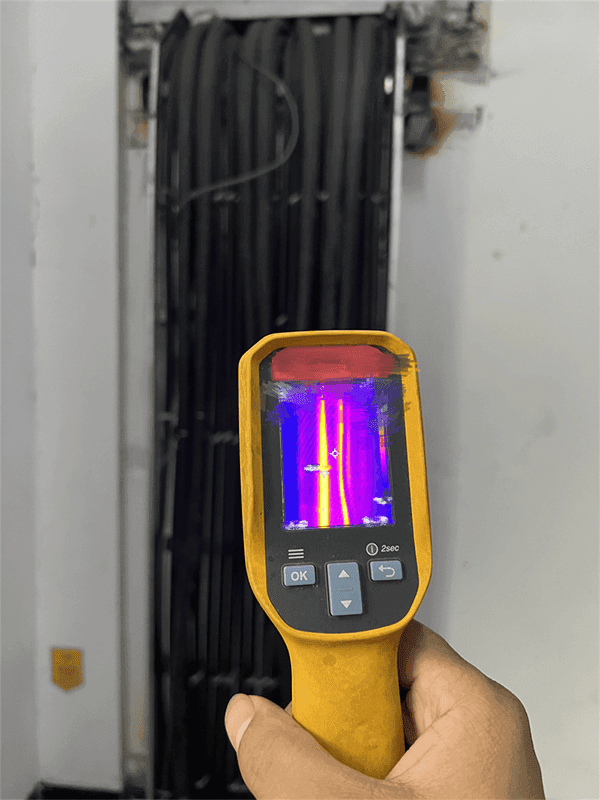

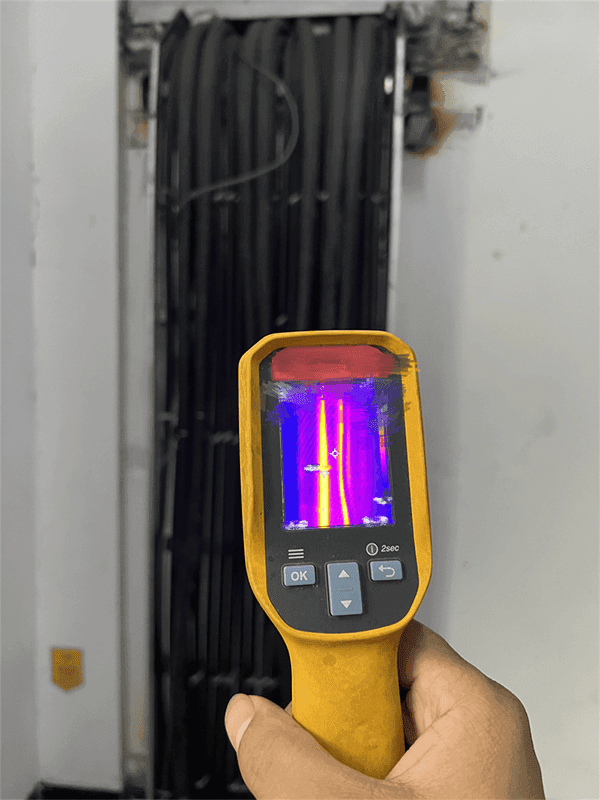

The consequences of current deviation are very serious. Conductors with high current will experience abnormal heating, and conductor heating will accelerate insulation material aging. After insulation aging, its insulation performance will decline, easily causing safety accidents such as leakage, and may even cause short circuits and fires.

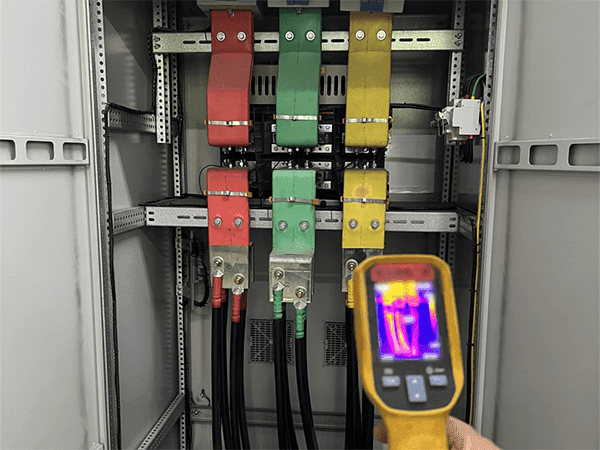

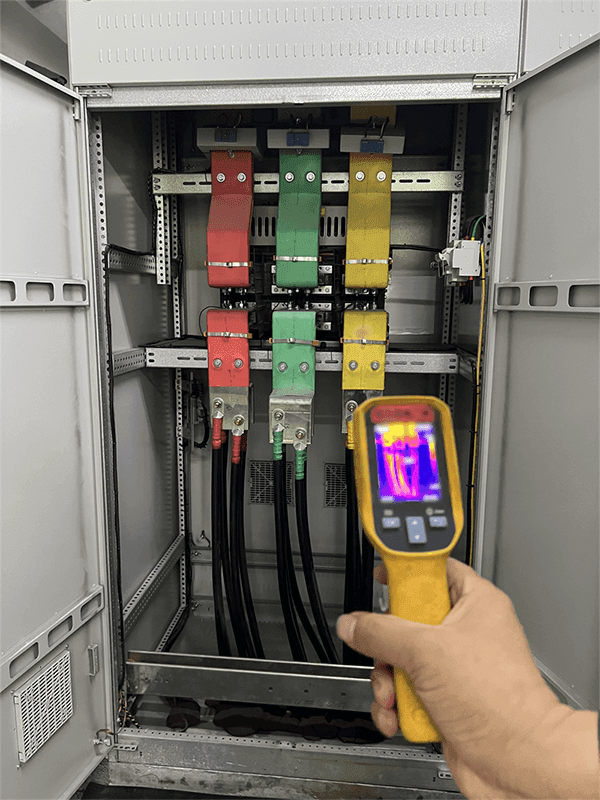

Moreover, the more complex the situation with high current, dense wiring, and parallel cables, the more attention current deviation problems require.

How to reduce the probability of current deviation?

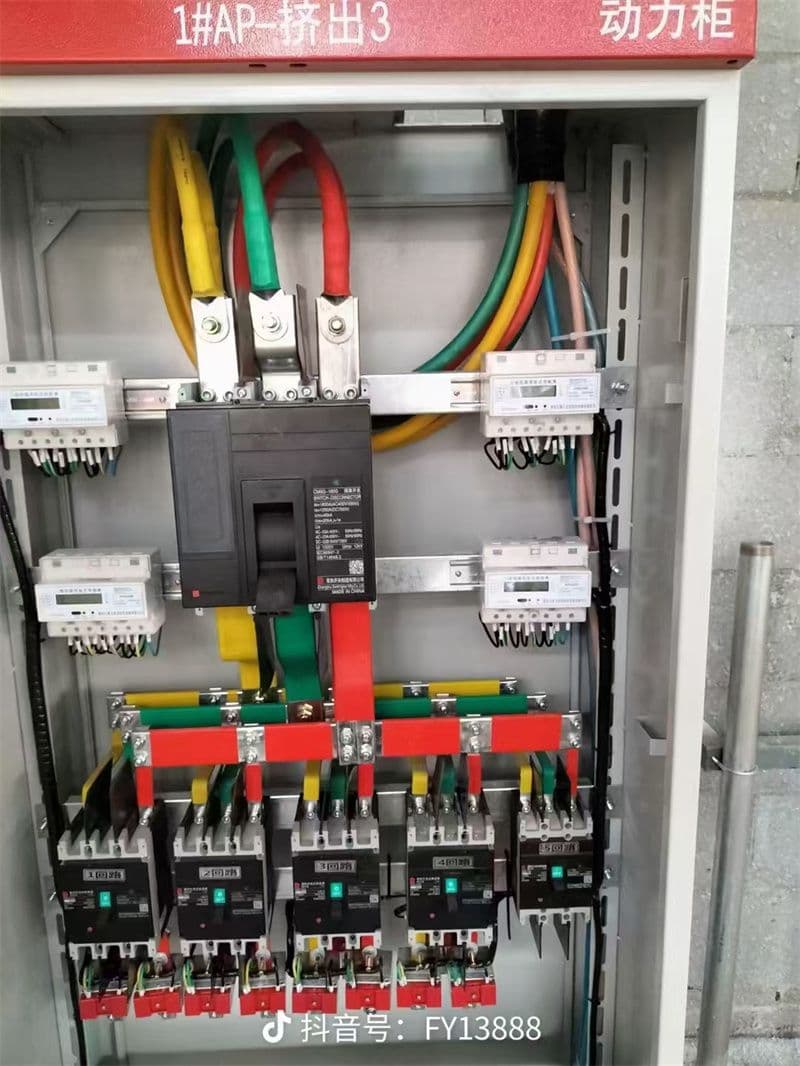

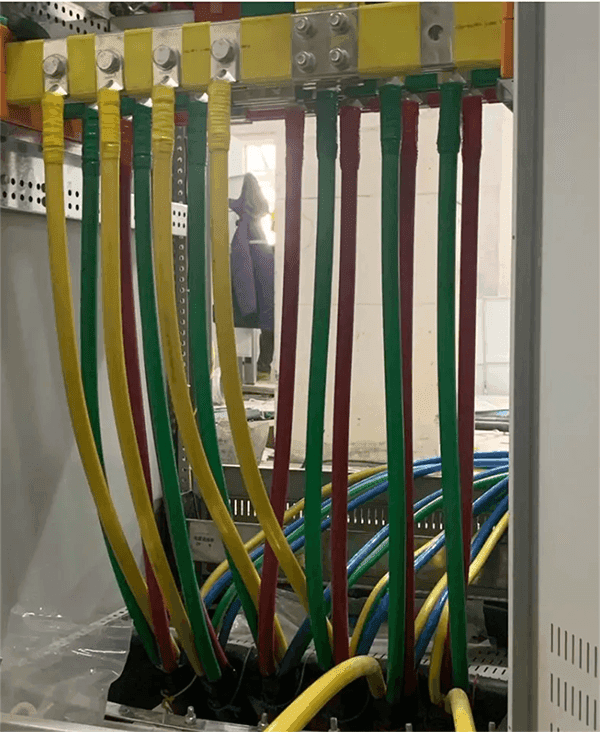

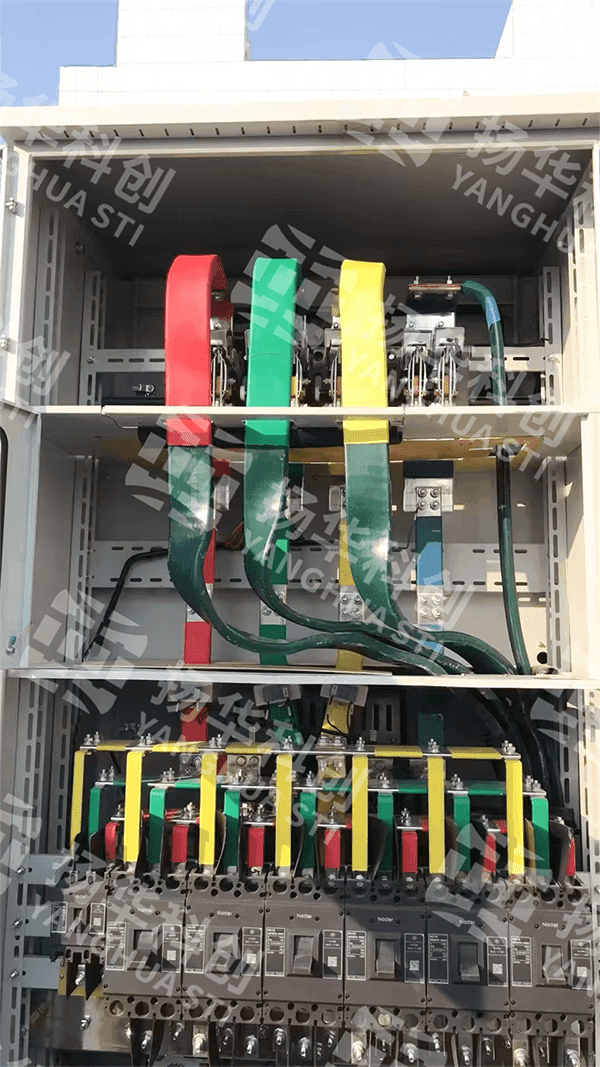

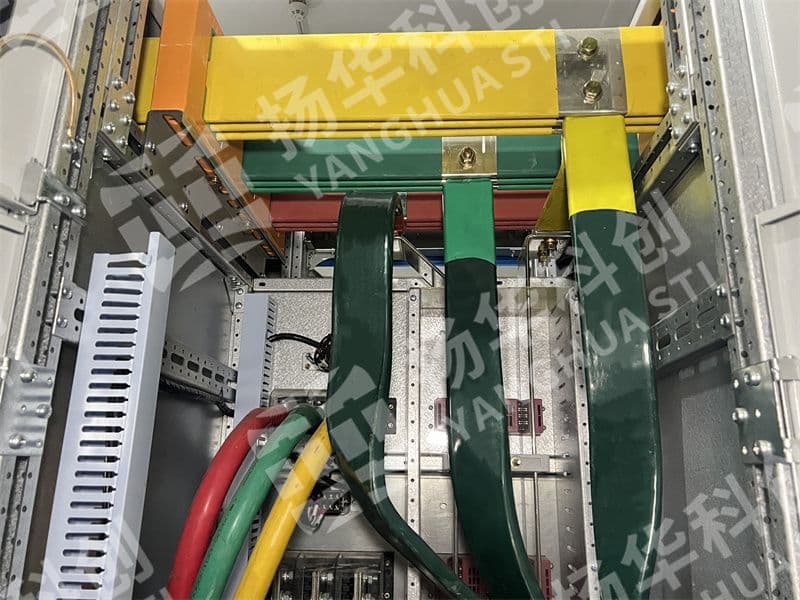

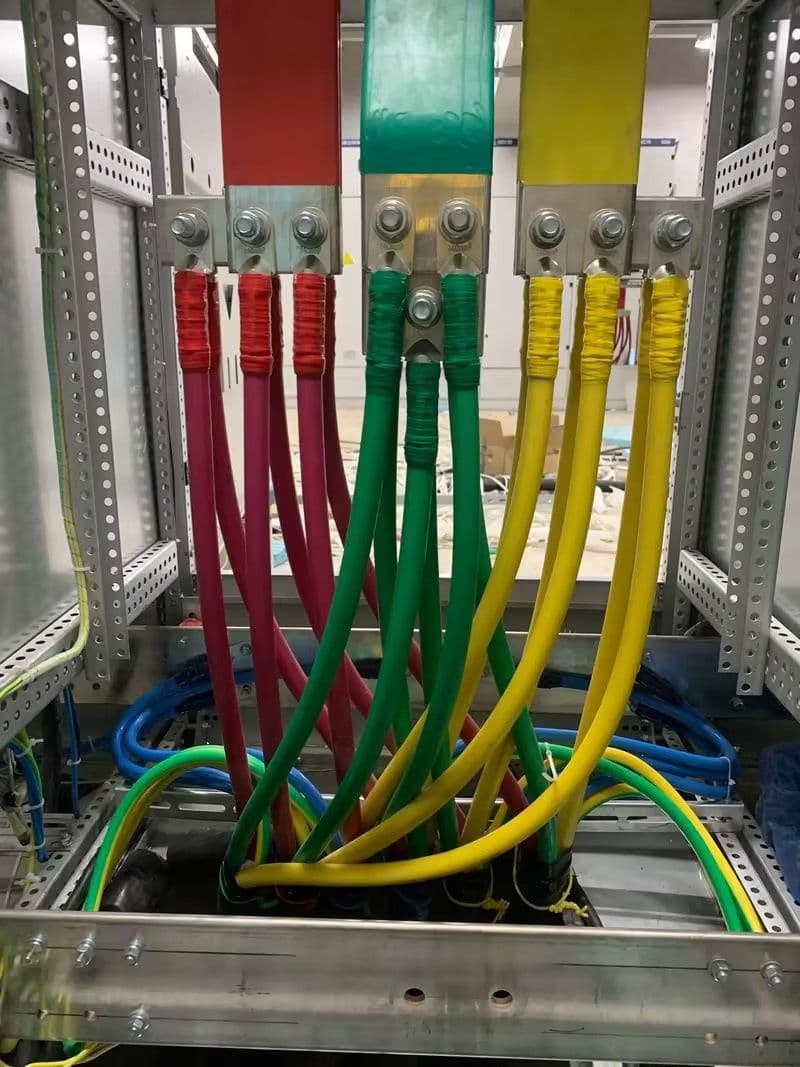

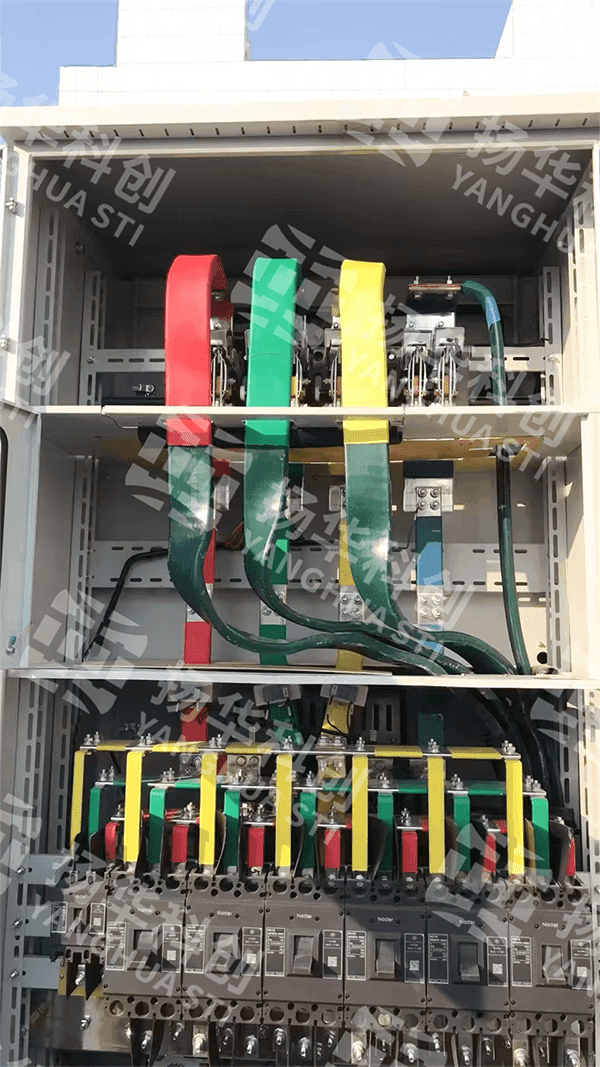

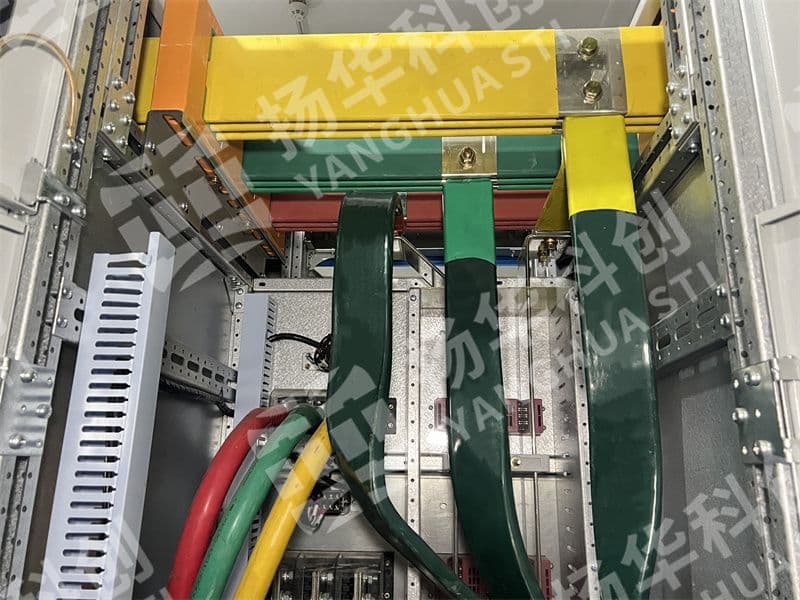

To effectively reduce the probability of cable current deviation, high-current flexible busbars are a good solution.

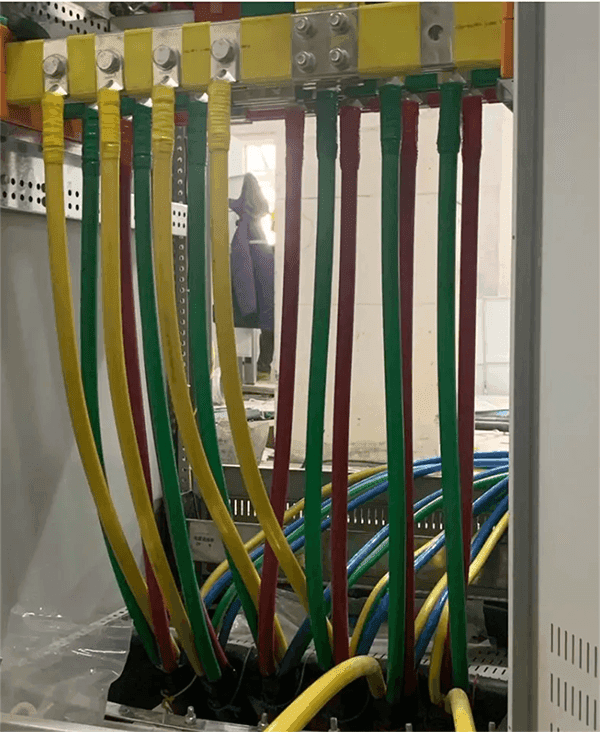

High-current flexible busbars have large single conductor current capacity, covering 200-6300A.

This characteristic allows them to reduce the number of parallels needed to meet the same power requirements, or even eliminate the need for multiple parallels. Compared to multiple parallel cables, this reduces installation complexity and potential problems.

Moreover, the connection method for high-current flexible busbars is more convenient, allowing direct drilling for connections without installing copper lugs.

This not only reduces installation costs and difficulty but also greatly reduces the possibility of current deviation caused by improper copper lug installation or poor contact surface connections.

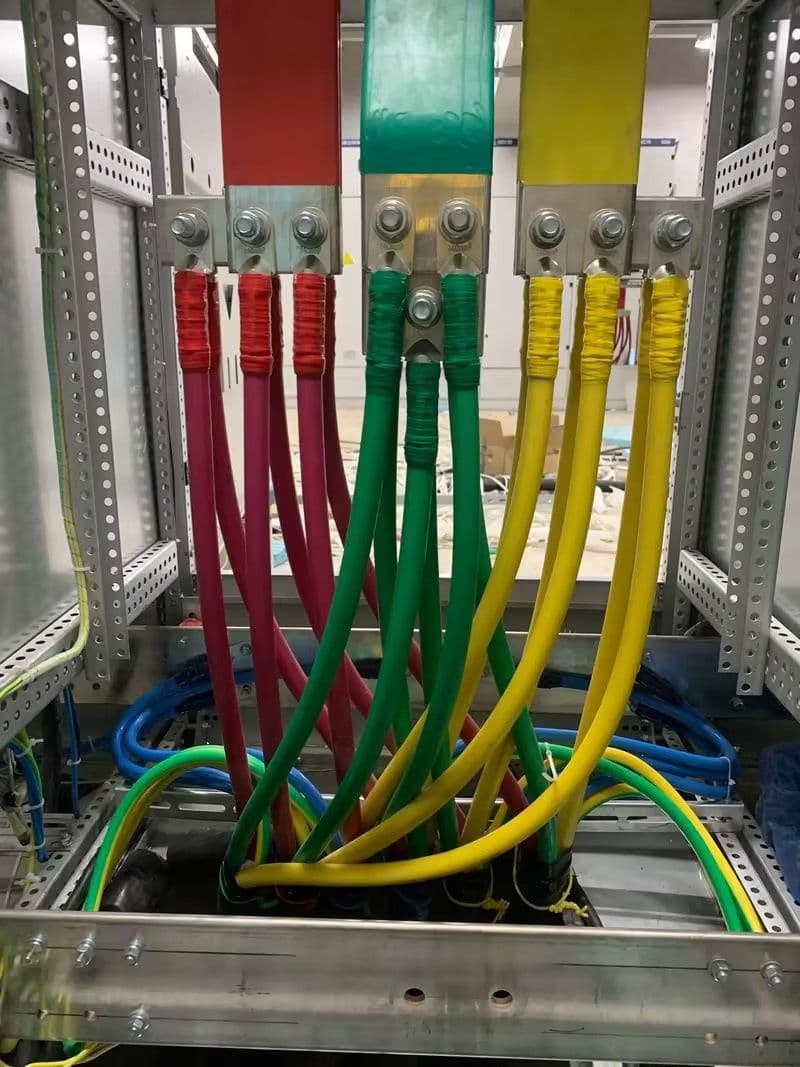

Many newly built commercial buildings and industrial plants have adopted high-current flexible busbars in their power distribution systems, with good operational results, greatly improving the safety and stability of electrical systems.

If you are interested in electrical knowledge or want to learn more about cable operation and electrical safety, welcome to follow us. We will provide you with more professional and practical electrical knowledge!

Focused on High Current Flexible Busbar Innovation, Providing Safe and Efficient Solutions for Power Transmission