Back to articles

Chemical Plant Multi-core Cable Connections Causing Problems vs. Flexible Busbar

David Doe

11/7/2025

Summary

How many multi-core cable connections have you made in chemical plants? This is the power distribution of a large chemical enterprise's plant, with numerous black cables intertwined between equipment like an impenetrable "cable forest," which is quite spectacular. Chemical plants operate 24 hours a day without interruption, and large equipment typically requires over 1000A...

How many parallel cable connections have you dealt with in chemical plants?

An image uploaded to Strapi called this-shrimp-is-awesome

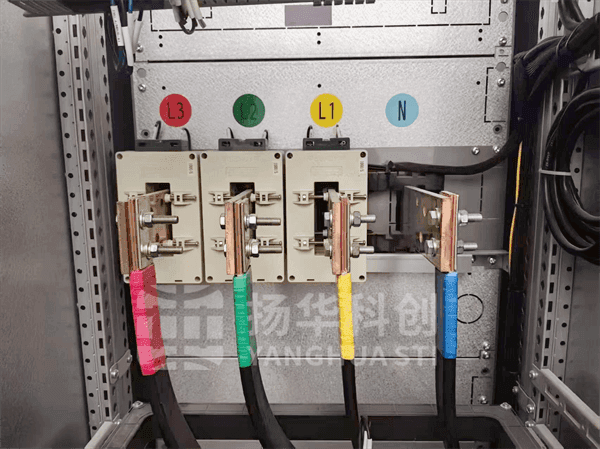

This is the distribution system of a large chemical enterprise plant, with numerous black cables weaving into a network between equipment, like an impenetrable 'cable forest,' quite spectacular.

Chemical plants operate 24 hours non-stop, with large equipment typically requiring currents above 1000A. Over 80% of workshop main cables use 4-8 parallel designs, with some old plants even showing extreme cases of 10 parallel cables.

This 'quantity stacking' approach essentially uses simple addition to address complex needs, laying hidden dangers for safety.

What do chemical plant power systems fear? Besides high current, invisible water vapor and dust are 'invisible killers'!

Due to limited single cable current capacity, multiple parallel connections (i.e., 'multiple parallels') are needed to increase load capacity. However, multiple parallel cables present the following problems:

① Uneven current distribution, with some cables facing dramatically increased overload risks.

② Multiple parallel cables lead to tight installation space and reduced heat dissipation efficiency.

③ Doubled number of connections, more troublesome installation, increased failure points (each additional parallel increases connection hazards by over 30%). For example, when workshops need to carry currents above 1600A, at least 6 parallel 185mm² cables are required.

④ Steam, acid-alkali dust, equipment vibration, high temperature, and other environmental factors in chemical plants will infinitely amplify the defects of multiple parallel cables, making later troubleshooting and maintenance difficult for multiple parallel cables.

Flexible busbars easily solve these problems~

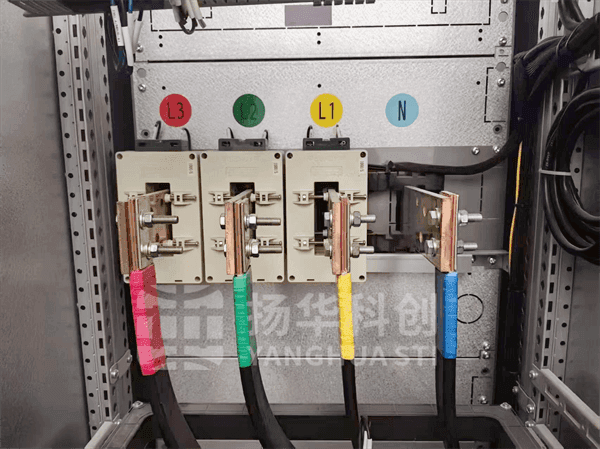

Highlight 1: High-current flexible busbars have large single conductor current capacity, greatly reducing the number of parallels needed while being able to run long distances, meeting IP68 high standards, suitable for both indoor and outdoor installation.

Highlight 2: Greatly reduced number of connections! High flexibility allows direct bending within bending radius without needing turning connections; no intermediate connections needed for long-distance installation, preventing water vapor and various dusts from penetrating, more secure!

Highlight 3: Small size, light weight, convenient installation and connection! Connection with copper bars only requires drilling, installation can go through cable trays, conduits, trenches, etc.

Focused on High Current Flexible Busbar Innovation, Providing Safe and Efficient Solutions for Power Transmission