Metallurgy & Chemical Flexible Busbar Solutions

Heavy-duty high current busbar solutions for harsh industrial environments with electrical busbar systems

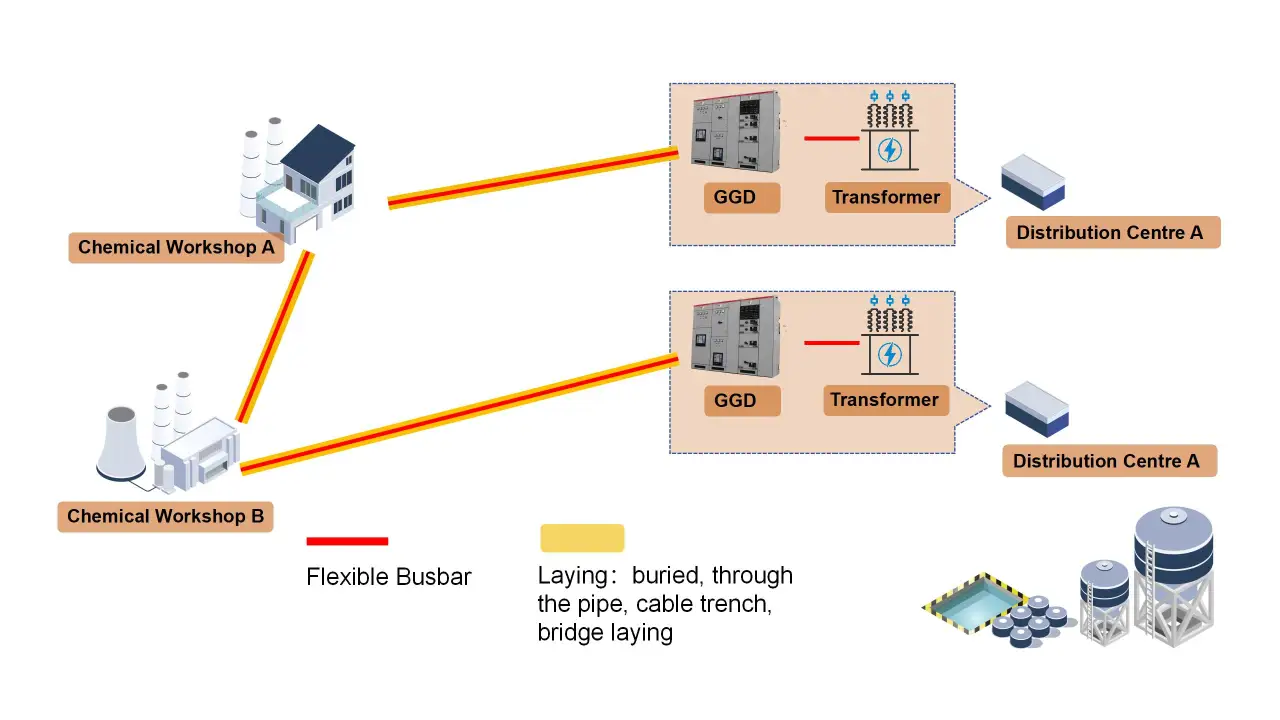

Deliver reliable power in the harshest industrial environments with our metallurgy and chemical flexible busbar solutions. Designed for steel mills, chemical plants, and refineries, they provide exceptional durability and performance in extreme conditions using flexible copper busbar technology.

Key Highlights

- Corrosion-resistant materials for electrical busbar systems

- High-temperature performance with flexible copper busbar

- Chemical resistance using high current busbar technology

- Explosion-proof designs available for industrial busbar applications

Typical Applications

- Steel mills high current busbar

- Chemical plants electrical busbar systems

- Refineries flexible copper busbar

- Smelting operations industrial busbar applications

Advantages

Extreme Environment Performance

Engineered to operate reliably in temperatures up to 200°C and corrosive chemical environments.

Safety Compliance

Meets stringent safety standards for hazardous industrial environments including ATEX certification.

Long Service Life

Specialized materials and construction provide extended service life even in harsh conditions.

Gallery

High-temperature busbar

Reliable power delivery in extreme heat conditions.

Corrosion-resistant links

Durable interconnects for chemical exposure environments.

Explosion-proof routing

Engineered options for hazardous industrial zones.

Technical Specifications

| Parameter | Value |

|---|---|

| Current Rating | Up to 6000A |

| Voltage Rating | Up to 1.5kV |

| Operating Temperature | -40°C to +200°C |

| Chemical Resistance | PTFE/PFA coating available |

Have a Project in Mind?

Download the full specification sheet for more details or get in touch with our experts to find the perfect solution for you.